Table of Contents

Last Updated January 10, 2024

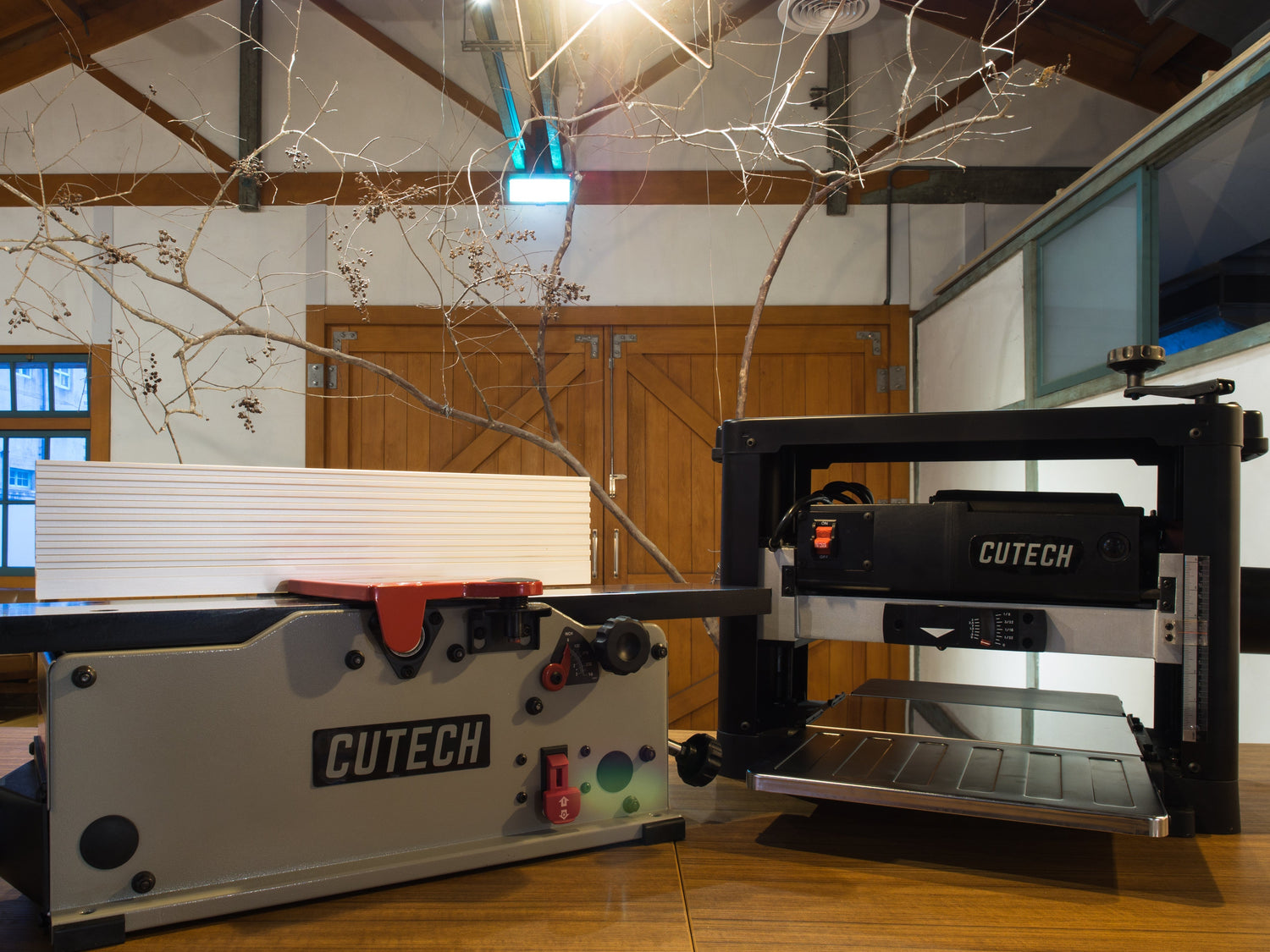

What is a Jointer?

A jointer is used to square edges and flatten single faces of wood. Cutech’s jointers accomplish this by using spiral cutters that mill the board from the bottom. In short, this machine is used to straighten out any imperfections in the wood such as bowing, twisting, and/or cupping of wood while shaping its edges. After a few passes, a surface will be perfectly flat. Once this is done, the wood can be reoriented with the jointer fence to square up whichever edge is facing the spiral cutters.

Learn more about WHAT IS A WOODWORKING JOINTER and HOW TO USE A JOINTERWhat a Jointer Can't Do

A common misconception is that a board can be flipped over and milled on the other side to achieve symmetry and uniform thickness. This, however, is not the case. While you will get two flat surfaces on either side of the board, the thickness of the board will not be consistent lengthwise. To use an analogy, picture yourself cutting a piece of paper into a square freehand with a pair of scissors. While your cuts will be straight, the edges themselves may not be completely parallel with opposing edges creating a lopsided square. So how do we ensure that both sides of the wood are parallel? This requires a planer.

Learn more about CUTECH’s benchtop jointer with spiral cutterhead.- Efficiently make the boards' face and edge straight and true

- Spiral cutterhead provides easier knife changes & lower noise volumes than the straight knife cutterhead

- CUTECH's 2-sided inserts sitting 90 against the cutterhead support results in a smoother finish

- Any damage to individual inserts can be changed out. In comparison to straight blade machines, any damage will require the costly replacement of all knives in the machine

What is a Planer?

The role of a planer is a simple but important one. In short, its primary function is to create two flat plane surfaces (hence the name “planer”) in wood so that they could be joined. The working mechanism behind a planer is as follows.

Rollers apply pressure and guide wood through an array of spiral cutters that mill the surface layers of wood.

This is a secondary process to jointing that ensures uniform thickness and symmetry.

We can think of planing as “fine tuning” the work done by a jointer. Back to the analogy of cutting paper, once you have cut out your square, you want to ensure that all opposing sides are parallel and cut to a desired thickness.

While using scissors can create straight lines and descent angles, i.e., the jointer, you would want a device that is able to ensure that the paper forms a perfectly symmetrical square, i.e., the planer.

A planer is all about precision and symmetry and the Cutech product line can be programmed to achieve any desired thickness within very tight tolerances.

Learn more about WHAT IS A WOOD PLANER USED FOR?

What a Planer Can't Do

Although planers serve a very useful purpose, there are some tasks that are best left to other equipment.

A planer's primary function is to take thick boards and make them thinner. The board must already have a flat surface so that it can be placed downwards on the bed in order for the planer to take off the top layers.

A planer is also not ideal for woodworking which may involve cutting angled edges. Also, planers use pressure rollers to pull boards which will not function correctly if the boards are cupped, warped, or twisted.

Addressing both of these issues is a job best suited for a jointer. In short, anything beyond thicknessing a board is not an ideal application for a planer.

Learn more about CUTECH’s benchtop planer with spiral cutterhead.

- Efficiently make the boards uniform in thickness

- Spiral cutterhead provides easier knife changes & lower noise volumes than the straight knife cutterhead

- CUTECH's 2-sided inserts sitting 90 against the cutterhead support results in a smoother finish

- Any damage to individual inserts can be changed out. In comparison to straight blade machines, any damage will require the costly replacement of all knives in the machine

Jointers and planers work symbiotically to create the precise cuts of wood required by serious woodworking hobbyists. This allows a greater variety of wood to be used that may not have been an option before with pre milled lumber from big box stores.

MAIN DIFFERENCES BETWEEN A JOINTER AND A PLANER

Understanding the distinct roles and capabilities of a jointer and a planer is crucial for woodworking. Here are the main differences between a jointer and a planer:

Primary Function

- Jointer: A jointer's main job is to flatten one face of a board and square up an edge. It's the first step in making a warped, twisted, or bowed board flat and true.

- Planer: A planer, on the other hand, is used to make the opposite face of the board parallel to the first flattened face. It ensures uniform thickness across the entire length and width of the board.

Working Mechanism

- Jointer: It has a flat bed with blades in the middle. The wood is passed over these blades to create a flat surface.

- Planer: A planer has rollers that feed the wood through, and a cutter head that trims the wood to a consistent thickness.

Type of Surface Treated

- Jointer: Ideal for treating warped or twisted surfaces and edges.

- Planer: Best for surfaces that are already somewhat flat but need uniform thickness.

Size and Shape Limitations

- Jointer: Typically limited by the width of its bed. Wider boards than the bed cannot be flattened.

- Planer: Can handle wider boards, but the thickness and how much material can be removed in one pass are limited.

Sequential Use in Projects

- Jointer: Generally used first to create a flat reference surface and a squared edge.

- Planer: Follows the jointer to bring the board to its final thickness and smoothness.

SYNERGY OF JOINTERS AND PLANERS IN FINE WOODWORKING

A jointer and a planer are complementary tools in woodworking. For achieving the best results in fine woodworking projects, using both jointers and planers in tandem is highly recommended. These two tools complement each other's capabilities, leading to a more efficient and precise woodworking process.

Woodworking Steps:

- Initial Flattening with a Jointer: A jointer is ideal for creating a flat surface on one side of the board. It removes warps, twists, or bows, which is crucial for any fine woodworking project. The jointer's ability to create a perfectly flat and straight edge sets the foundation for further planing.

- Thickness Uniformity with a Planer: Once one side of the board is flattened by the jointer, the planer comes into play to make the opposite side parallel to the first. This ensures uniform thickness throughout the length of the board. A planer works best when it starts with one flat side, which is where the jointer's role is vital.

- Achieving Perfect Right Angles: After flattening one face and one edge on the jointer, the planer can be used to create a second face parallel to the first. This process guarantees that the final piece of wood is not only of uniform thickness but also perfectly rectangular, with right angles on all corners.

- Enhanced Precision and Finish: The combination of a jointer and a planer allows for greater precision in woodworking. The jointer ensures that the initial surfaces are flat and true, while the planer brings the piece to its final thickness with a smooth finish, essential for fine woodworking.

In conclusion, for fine woodworking projects where precision and finish are paramount, the jointer and planer are indispensable tools. Their combined use ensures that wood pieces are perfectly flat, straight, and of uniform thickness, which are fundamental requirements for high-quality woodworking.

Jointer-Planer Combo

A jointer/planer combination machine uses a single cutterhead to joint and plane boards.

Typically the jointer is mounted on top with a planer directly underneath. The combination jointer/planer is a popular machine in Europe due to its small footprint.

In recent years, it has gained the attention of US woodworkers as a way to save space in small workshops.

Comparison Between Jointer, Planer & Jointer-Planer Combo

Jointer Planer

1. Flattening single surfaces2. Edge jointing

3. Chamfering

Planer

1. Even Thicknessing2. Unifying boards in thickness

Jointer-Planer Combo

Saves on floor spaceLearn more about Evolution of the CUTECH Spiral Cutterhead.

JOINTERS & PLANERS FAQ

Q: What is the difference between a jointer and a planer?

A jointer is primarily used for flattening and straightening the face or edge of a board, while a planer is used for reducing the thickness of a board to achieve a consistent thickness.

Q: Can a planer be used as a jointer?

No, a planer cannot be used as a jointer. A planer's primary function is to reduce the thickness of a board, whereas a jointer is specifically designed for flattening and squaring edges or faces.

Q: What are the advantages of using a spiral or helical cutterhead?

Spiral or helical cutterheads, found in some jointers and planers, offer several advantages. They produce a smoother finish, reduce noise, minimize tear-out, and often require less power compared to traditional straight-knife cutterheads.

Q: How do I maintain my jointer or planer?

Regular maintenance of jointers and planers includes cleaning the machine, lubricating moving parts, checking and adjusting the blade alignment, and ensuring the blades are sharp. Following the manufacturer's instructions and guidelines is crucial for proper maintenance.

Q: How do I prevent tear-out when using a jointer or planer?

To minimize tear-out, it's important to pay attention to the direction of the wood grain and ensure that the wood is fed into the jointer or planer in the correct orientation. Additionally, using a slower feed rate and sharp blades can also help reduce tear-out.

Q: What safety precautions should I take when using jointers and planers?

When using jointers and planers, it's important to wear appropriate safety gear, such as safety glasses, hearing protection, and dust masks. Additionally, understanding the machine's operating instructions, maintaining a clean work area, and using proper feeding techniques are essential for safe operation.