Last Updated January 5, 2026

In the realm of woodworking, a jointer is an indispensable tool that can transform rough lumber into a polished piece ready for your next project. This article aims to provide a comprehensive guide on woodworking jointers. We will then delve into the key factors to consider when choosing a benchtop jointer. Furthermore, we'll share our top picks for the best benchtop jointers for 2025. Whether you're a seasoned woodworker or a beginner, this comprehensive guide aims to enhance your woodworking journey.

Table of Contents

What is a Wood Jointer?

A woodworking jointer is a handy tool to quickly flatten one face and one side of a board. This step is necessary before a board can be thicknessed with a planer. A jointer can be used to straighten out boards that are cupped or warped thus saving wood that would otherwise be unusable.

A wood jointer consists of several key components, including in-feed and out-feed tables, a cutting head (cutterhead), and a fence.

Related article: How to Use a Jointer: 4 Easy Steps to Perfect Wood & Pro Tips

Key Components:

- In-feed and Out-feed Tables: These tables support the wood as it passes through the jointer. The in-feed table is adjustable, allowing for precise control over the amount of material removed.

- Cutterhead: Located between the in-feed and out-feed tables, the cutterhead contains sharp blades or cutters that shave off a thin layer of wood to create a flat surface.

- Fence: A vertical guide that ensures the wood is fed through the jointer at a consistent angle, typically 90 degrees.

What is a Wood Jointer Used For?

A wood jointer is an essential tool for any woodworking project that requires smooth, flat surfaces and precise edges. Here's how it's commonly used:

Flattening Surfaces

The primary use of a wood jointer is to flatten one face of a board. This is essential for preparing rough, warped, or uneven lumber for further processing. By creating a perfectly flat surface, the jointer ensures that the wood can be used accurately in various woodworking projects.

Squaring an Edge

In addition to flattening surfaces, a jointer is also used to square the edges of a board. This is crucial for creating tight, seamless joints when assembling pieces of wood. Squaring the edges involves passing the board through the jointer with the edge against the fence, producing a straight, perpendicular edge to the flattened face.

Removing Warps and Twists

A jointer is highly effective in removing warps and twists from lumber. Warped or twisted boards are difficult to work with, but a jointer can correct these imperfections by shaving off the high spots and creating a uniform thickness.

Preparing Wood for Planing

While a jointer can create flat surfaces and square edges, it is often used in conjunction with a thickness planer. The jointer prepares the wood by flattening one face and squaring one edge, making it easier for the planer to produce boards of uniform thickness.

What’s the Difference Between Wood Jointer and Planer?

If you’re diving into woodworking, you’ve probably come across two essential machines: the jointer and the planer. While both are used for preparing wood, they serve different functions in creating smooth, flat surfaces.

- Wood jointer: A jointer is specifically designed to flatten one face of a board and square up one edge. When dealing with rough or warped lumber, the jointer ensures a flat surface on one side and a perfectly squared edge, making the wood ready for further work.

- Wood Planer: A planer (or thickness planer) is used to make both faces of the board parallel and achieve a consistent thickness. After one face is flattened with the jointer, the planer smooths and levels the opposite face, ensuring both sides are even and parallel.

In short, the jointer flattens and squares, while the planer ensures uniform thickness. Together, they help transform rough wood into precise, workable material.

For more details, check out our extended guide: Jointer vs. Planer

Types of Wood Jointer

Wood jointers come in several types, each suited for different woodworking tasks and shop sizes. Here’s a brief look at the most common types:

1. Benchtop Jointer

A benchtop jointer is compact and designed to sit on a workbench, making it ideal for smaller workshops or hobbyists. While smaller in size, these jointers are still powerful enough for most home woodworking projects. They’re affordable, easy to move, and perfect for flattening smaller boards.

2. Closed Stand Jointer

The closed stand jointer features an enclosed cabinet base, which houses the motor and reduces noise. This type of jointer is more stable, offers better dust collection, and is ideal for serious woodworkers looking for durability and higher performance in their machines.

3. Open Stand Jointer

An open stand jointer has an exposed, lightweight frame that houses the jointer’s motor. While more affordable and easier to move around, it doesn’t provide as much stability or noise control as a closed stand model.

4. Long Bed Jointer

The long bed jointer has an extended table, making it ideal for handling longer boards with ease. This type of jointer is preferred by professionals who work with large materials, as the long bed ensures accuracy and stability across the length of the board.

5. Hand Jointer

For those who prefer traditional methods, a hand jointer is a manual tool used to flatten and square up wood edges. While it requires skill and effort, it’s a classic tool often favored by hand tool enthusiasts or for delicate tasks where machine precision isn’t needed.

Key Factors to Consider When Choosing a Benchtop Jointer

Jointers are straightforward machines and there's little variation between brands. The options available to the consumer are the size of the cutterhead, the type of knives, the material of the tables and the adjustability of the fence.

Size of the Cutterhead

Benchtop jointers come in 3 sizes, 6", 8" and 10". This corresponds with the maximum width of board a joint can handle. The small 6" jointer is limited to boards as wide as 6" so it is perfect for small jobs. The 8" and the 10" are more versatile since they can handle wider boards. The larger jointers also mean less biscuit jointing, an extra step in larger work pieces.

Type of Knives

The cutterhead size matches the width of the jointer but the style can be a straight blade cutterhead or a spiral cutterhead. The straight blade will have 2-3 blades running the length of the cutterhead that cuts the wood in long thin strips. The spiral cutterhead uses small cutters called inserts that are staggered on 6 rolls of the cutterhead.

Material of the Tables

The tables are required to be perfectly flat in order to produce a flat surface on boards. Table materials vary from aluminum to Teflon-coated to even cast iron. The most common tables seen on benchtop planers are aluminum due to its durability and light-weight qualities. Cast iron is seen most often on larger jointers which on benchtop jointers tend to add quite a bit of weight to the machine making them less portable.

Adjustability of the Fence

The fence is commonly made of extruded aluminum. Its role is to guide the board across the table. It often has preset angles adjustments as well so that making an angled edge joint is fast and easy.

How to Use a Jointer

A jointer has an infeed and outfeed table with the cutterhead in between them. The infeed table is adjusted down so that when the board is pushed it makes contact with the cutterhead. The depth of cut correlates with how low the infeed table is lowered. The outfeed table supports the board after it has passed the cutterhead. A board can be jointed on one surface and one side as the start to squaring up the board.

Wood Jointer FAQ: Common Questions Answered for Beginners

Q1: Is a wood jointer worth it?

Yes, a wood jointer is absolutely worth it if you do any amount of woodworking that involves flattening rough lumber or preparing boards for glue-ups. A jointer allows you to create perfectly flat faces and square edges, which are essential for accurate, high-quality builds. It saves time compared to manual methods and improves precision, especially when working with warped, bowed, or twisted boards.

Q2: Can I joint wood without a jointer?

Yes, it’s possible to joint wood without a jointer using alternatives like a hand plane, a table saw with a jointer jig, or a planer with a sled. However, these methods require more setup time, experience, and skill to achieve the same level of accuracy. While viable for hobbyists or those on a tight budget, having a dedicated jointer streamlines the process and improves consistency, especially for repeated tasks.

Q3: Can I use a jointer on both sides?

No, a jointer is designed to flatten only one face of a board to create a reference surface. Flattening both sides with a jointer can result in uneven thickness because it doesn't ensure the two faces are parallel. Instead, use a planer after jointing one face—this way, the planer references the flat face and creates a second face that’s both flat and parallel. For consistent results, always pair a jointer with a planer.

Q4: How to stay safe with a jointer?

Always follow these key safety tips:

-

Keep hands away from the cutterhead—use push blocks or push paddles.

-

Never remove the cutterhead guard unless performing special operations like rabbeting, and only with extreme caution.

-

Feed the board with the grain to reduce tear-out and kickback.

-

Ensure tables are clean and waxed to avoid forceful feeding.

-

Never joint boards thinner than ½ inch, as they may shatter or kick back.

Best Benchtop Jointers Worth Considering in 2026

WEN JT630H 10-Amp 6-Inch Spiral Benchtop Jointer

The portable WEN 6" jointer is a great companion to have on job sites. The spacious 30" x 6" table provides the right amount of support for small jobs. The flexibility to remove 0 to 1/8" of material with each pass, makes flattening boards a fast and easy process. With a price tag of $279.42, it is priced competitively in the market. The 2 year warranty is a nice bonus over most companies that only guarantee their machines for 1 year.

|

Feature |

the portable jointer is a great companion to have on job sites |

|

Type |

Benchtop jointer |

|

Motor |

10 amps |

|

Cutting Width |

6 inches |

|

Cutterhead |

Spiral |

CRAFTSMAN Benchtop Jointer, 10-Amp (CMEW020)

The Craftsman 6" jointer with its signature red and black colors is worthy of mention. A well built machine with easy setup out of the box. This traditional straight blade machine with variable speed control from 6,000 RPM up to 11,000 RPM is ideal for edging, flattening and face jointing. Craftman offers a generous 3 year limited warranty for this benchtop model.

|

Feature |

traditional straight-blade machine with variable speed control, ideal for edging, flattening, and face jointing |

|

Type |

Benchtop jointer |

|

Motor |

10 amps |

|

Cutting Width |

6 inches |

|

Cutterhead |

Straight |

RIKON Power Tools 20-600H 6" Benchtop Jointer with Helical Cutter head

The Rikon 6" benchtop jointer is designed for ease of use. The Helical style cutterhead holds 12 2-sided high speed steel inserts, making replacements cost effective and easy. The adjustable fence allows for quick angle cuts with presets at 45 degree and 90 degree. Rikon stands by their products in offering a staggering 5 year warranty on this model.

|

Feature |

designed for ease of use, this model offers a staggering 5-year warranty |

|

Type |

Benchtop jointer |

|

Motor |

10 amps |

|

Cutting Width |

6 inches |

|

Cutterhead |

Helical |

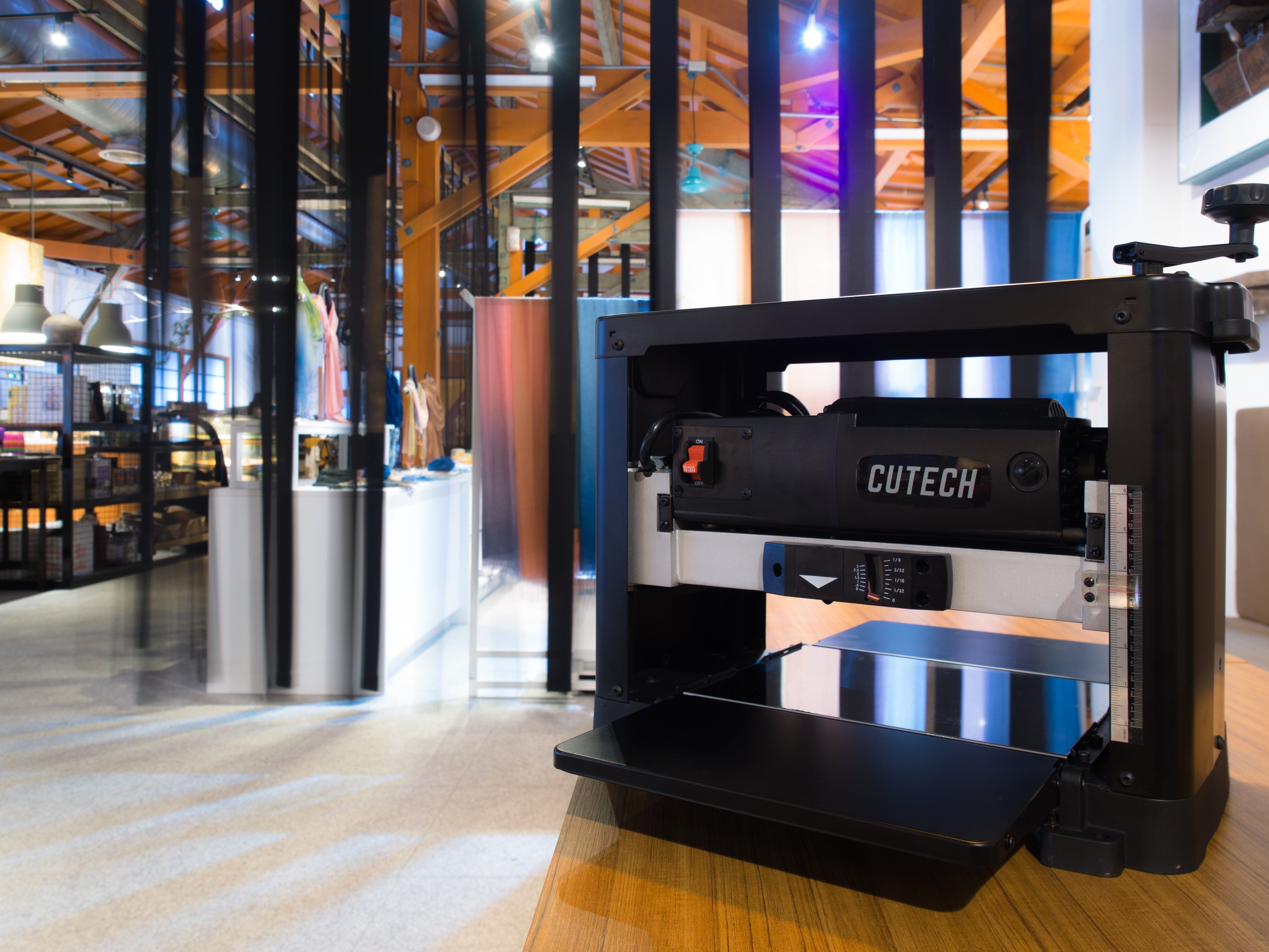

Quality Woodworking Jointers - Cutech

Cutech 40180HB

The Cutech 40180HB 8" jointer with 120 Volt 10-Amp motor is a classic standard benchtop jointer indispensable for the weekend warrior. Engineered for precision, the adjustable depth of cut can perform cuts from 1/32" (?) to 1/8". The extendable teflon-coated tables offer support for longer boards.

Learn more about CUTECH 40180HB Jointer

Cutech 40180HI

The latest addition to the Cutech 8" jointer family is the 40180HI jointer with the much anticipated cast iron tables. Along with a longer fence and fence enhancement brackets, this robust machine handles jobs, small and large, with flawless cuts and exact precision.

Learn more about CUTECH 40180HI Jointer

Cutech 401100HI

A step up from the rest, the new 401100HI 10" cast iron jointer is a stellar addition to any workshop. Exceptional craftsmanship from the expandable cast iron tables, to the 24" long fence and precision spiral cutterhead, this jointer will easily become a favorite.

Learn more about CUTECH 401100HI Jointer

Cutech 401120HI

Introducing the sizable, extra wide 12” Cutech jointer with the much sought after cast iron tables. The beloved spiral cutterhead straightens out any board irregularities with ease. The 401120HI comes standard with a longer fence and fence enhancement brackets to keep tolerance tight from start to finish. Unrivaled 12-amp Motor gives this jointer extra muscle for tough jobs. Well thought out new design features along with increased performance capable of tackling large jobs.

Learn more about CUTECH 401120HI Jointer