Table of Contents

- What is Planer Snipe?

- What Causes Snipe?

- How to Reduce Planer Snipe. 4 Essential Ways to Prevent / Minimize Snipe

- 1. Use sacrificial boards of equal thickness

- 2. Use a jointer to flatten the first surface.

- 3. Make certain that boards are sufficiently supported.

- 4. Check the position of extension tables.

- Using Cutech Planers to Minimize Snipe

- Planer Snipe FAQ

What is planer snipe and what causes snipe? How to eliminate or fix snipe on a planer? Don’t let snipe ruin your woodworking projects! In this article, Cutech will share you 4 essential ways to minimize planer snipe.

Last Updated January 09, 2024

What is Planer Snipe?

Professional looking woodworking projects don't just happen on their

own. They start with woodstock that's milled to precision. So don't

let snipe get in the way of your professional-quality project.

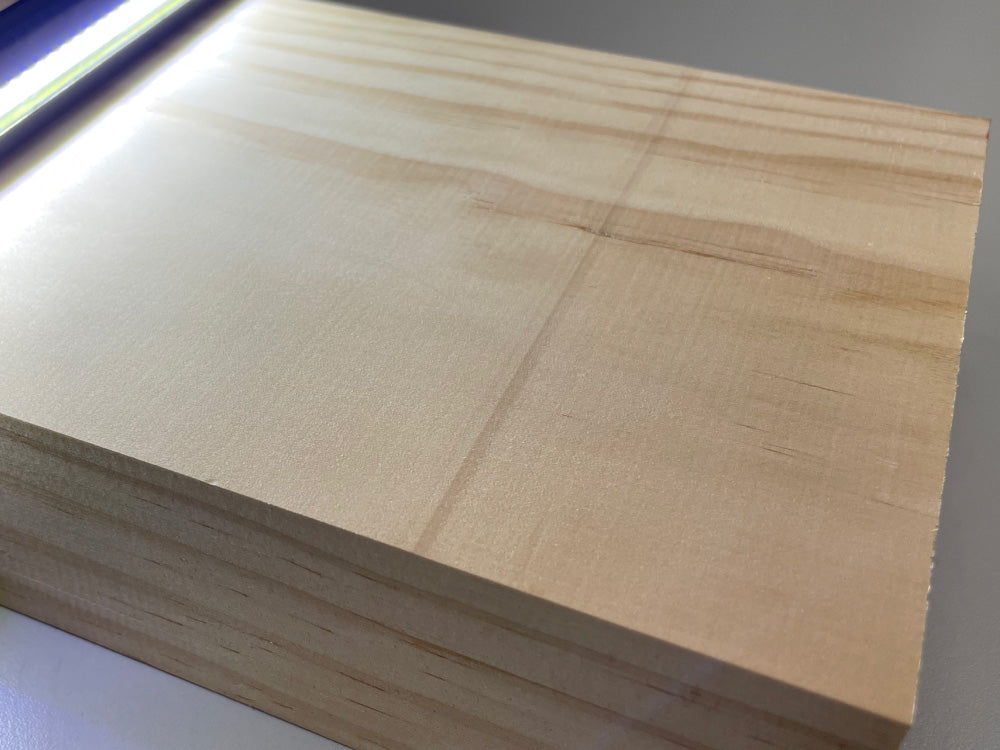

Snipe is when a board is noticeably cut deeper on the lead end or tail

end after it passes through a benchtop planer.

What Causes Snipe?

Snipe occurs when an uneven force is created as the board passes under the Feed Rollers. The function of the Feed Rollers are essential on a benchtop planer and the downward force has to be significant to secure the board during the planing process. The force comes from the compression springs between the rollers and the Upper Frame where the cutterhead is mounted. While the roller is engaging to the board, the spring tension simultaneously presses up the Upper Frame.

When a board is initially fed into the planer, only the Infeed Roller is exerting downward pressure on the board. The same is true when the board is exiting the planer. During planing, the upper Frame is initially pressed up by the tension from the infeed side springs, then by all springs and finally by the outfeed side springs. As a result, both ends are cut deeper.

How to Reduce Planer Snipe. 4 Essential Ways to Prevent / Minimize Snipe

METHOD 1: USE SACRIFICIAL BOARDS OF EQUAL THICKNESS

Implementing sacrificial boards is a practical approach to prevent snipe on your finished workpiece. Place these boards, which should be of the same thickness as your workpiece, at both the beginning and end of the workpiece sequence. The sacrificial boards take the brunt of the snipe, sparing your actual project.

Safety Note: Ensure that these sacrificial boards are longer than the minimum length requirement for your planer model (e.g., 7 inches for Cutech planers) to maintain safety during operation.

METHOD 2: USE A JOINTER TO FLATTEN THE FIRST SURFACE

Since a planer works best when making a surface parallel to an already flat base, starting with a jointer can significantly reduce snipe. The jointer creates a flat initial surface, which the planer can then match, leading to a more consistent thickness and less snipe.

METHOD 3: ENSURE ADEQUATE SUPPORT FOR BOARDS

This is especially recommended for longer boards, since longer boards have an unsupported weight, which can pull down the ends during planing. To counter this, use stands or roller supports to maintain an even feed through the planer.

If stands are not available, manually supporting the board by gently lifting the end as it enters and exits the planer can also help. This technique doesn't eliminate snipe but can significantly reduce its occurrence.

METHOD 4: CHECK THE POSITION OF EXTENSION TABLES

Based on testing by Cutech engineers, the extension tables have a minor but still important role in preventing snipe. The key is to adjust the inner edges of these tables slightly lower than the central bed of the planer. This slight adjustment ensures that the wood transitions smoothly onto and off the planer bed, reducing the likelihood of snipe at the beginning and end of the cut.

By incorporating these four methods, you can effectively minimize snipe in your planing projects, leading to higher quality finishes and less material waste. Remember, each planer may have its specific adjustments, so always refer to your planer's manual for the best practices tailored to your equipment.

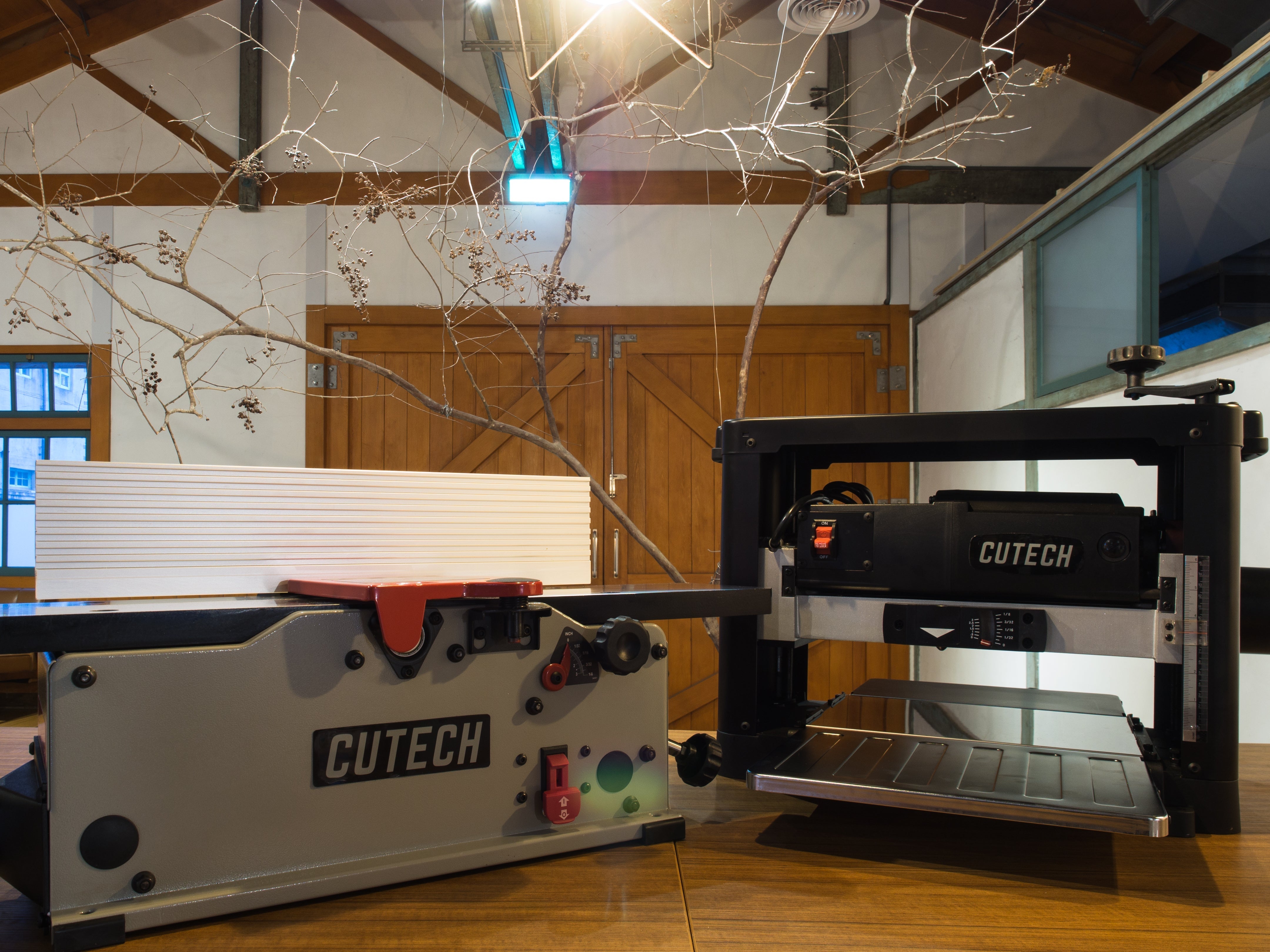

Using Cutech Planers to Minimize Snipe

CUTECH offers a planer model known as the 40200H that features

SNIPE LOCK. SNIPE LOCK helps reduce snipe by locking the

cutterhead into position when planing. Set the feature to unlock

when raising or lowering the cutterhead, then set it back to the

locked position before planing your workpiece.

The 40600H, 40700H and 40800H models utilize SNIPE MINIMIZER and 4 lead screws to mobilize the upper frame. Guideposts are not necessary with these

models because our patented SNIPE MINIMIZER gives a comparable

and, in some situations, better performance than the addition of the

snipe lock feature included in the 40200H.

Whether you are an experienced woodworker or someone just

starting out, don’t let the tools you use prevent you from doing your

best work. See the full line of CUTECH jointers, planers and

accessories on our website.

Planer Snipe FAQ

Do all planers have snipe?

The mechanism of the Feed Rollers causes Snipe but the function of the Feed Rollers are essential on benchtop planers. Therefore, snipe is noticeable if there are no additional snipe control mechanisms.

Do all jointers have snipe?

On a jointer, snipe can be eliminated by fine tuning the leveling between the Outfeed Table and the Cutter Tips.

How do I prevent / minimize snipe?

- Use sacrificial boards.

- Use a jointer to flatten the first surface.

- Make certain that boards are sufficiently supported.

- Check the position of extension tables.

Does a planer sled help with snipe?

A planer sled proves to be a valuable tool for mitigating snipe on thicker workpieces, particularly when the runners maintain a consistent thickness matching that of the workpiece. The sled facilitates uniform support and pressure during the entire planing process, thereby significantly reducing the likelihood of snipe occurrences at the ends of the workpiece.

Related article: What is a Wood Planer? A Guide to Choosing the Best Planer

How to Use a Planer: Master the Basics in 4 Easy Steps